In today’s competitive textile manufacturing landscape, production inefficiencies and frequent yarn breakage continue to challenge mill operators striving for consistency and quality. These issues not only drive up operational costs but also compromise fabric integrity and slow down weaving processes—impacting both profitability and reputation. Traditional sizing systems often lack the precision, control, and ease of maintenance needed to meet modern industry demands.

This is where advanced sizing technology steps in. With innovative solutions like Prosize and Isosize, manufacturers can now overcome these persistent challenges. From intuitive process control to revolutionary yarn treatment and chemical application systems, these technologies combine efficiency with innovation—offering lower maintenance, enhanced yarn performance, and optimized weaving output. This journal explores how Prosize and Isosize are redefining sizing in the textile industry by delivering both operational simplicity and superior fabric quality.

Advanced Sizing Technology

At Isosize, the size boxes feature a streamlined linear roller design, ensuring that the yarn is consistently guided and securely clamped within the wet zone. Equipped with a height-adjustable size tank and large, easy-to-access filters, the system is designed for effortless inspection and cleaning.

Taking innovation, a step further, the newest sizing and assembling machine Prosize introduces a cutting-edge chemical application system through its unique size box concept. Engineered for maximum efficiency, Prosize achieves the lowest size add-on while delivering the highest cover factor. All bearings are strategically placed outside the size liquor to minimize wear, while the bonded yarn guidance system ensures precision. Maintenance is significantly reduced, and all core components are easily accessible, streamlining routine servicing.

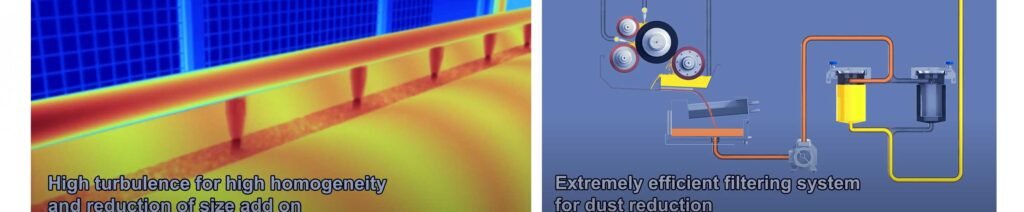

Thanks to its turbulent size application and sponge effect technology, Prosize enables a size add-on reduction of up to 10%, translating directly into cost savings and improved resource efficiency—all while maintaining top-tier performance in fabric quality.

Efficiency Operation & Yarn Control

Isosize has earned a strong reputation not only for its efficient performance but also for its exceptional ease of maintenance. The entire system is designed with low-maintenance components, making daily handling and long-term operation simple and worry-free. This user-friendly design helps reduce downtime and ensures reliable productivity on the production floor.

Prosize, while equally cost-efficient like Isosize, goes even further by addressing one of the most critical aspects of the sizing process: yarn elongation control. Its short wet-application zone, combined with 100% bonded yarn transport and the innovative SoftDry system, ensures minimal yarn stretch during sizing. This results in stronger yarns with reduced breakage, enhancing fabric integrity and weaving performance.

By minimizing mechanical stress on the yarn, Prosize preserves fiber strength, reduces production loss, and contributes to a smoother weaving process—making it a superior choice for manufacturers who demand durability, efficiency, and precision.

Superior Automation & Process Control

Building upon this excellence, Prosize takes innovation to the next level. Prosize introduces a next-generation mechanical design that delivers maximum weaving efficiency. Its superior size liquor homogeneity, combined with low yarn hairiness, minimal dust, and the elimination of stop marks, ensures outstanding fabric quality and top weaving performance.

The Isosize system is equipped with the state-of-the-art KARL MAYER Process Control System, designed to ensure premium quality and consistent reproducibility in every production run. With an intuitive, user-friendly software interface, operators benefit from seamless control, enhanced monitoring, and greater confidence in day-to-day operations. This advanced automation guarantees optimal results with minimal operator intervention.

By integrating cutting-edge control with advanced yarn treatment, Prosize allows textile producers to achieve higher output, fewer disruptions, and unmatched consistency — a clear choice for mills aiming for excellence in both quality and productivity.

Filsize-F: Precision Sizing for Finer Deniers with Maximum Control & Workplace Safety

Filsize-F is a sizing machine for filament yarns, offering precise tension control for the finest

deniers and consistent sizing quality across wide widths. Filsize-F (filament) features an advanced size box,

the hot air chamber covers open and close at the push of a button and also ergonomic design. All yarn sheet tensions are controlled by precise load cells, resulting in highest production speeds even with finer deniers.

Unlock the full potential of your factory’s production efficiency with cutting-edge solutions from Karl Mayer. Discover how advanced warp preparation technology can transform your operations, reduce downtime, and elevate fabric quality. Contact AGANSA today for expert guidance and tailored support.